Customized PE film for special features

1. Functional films such as anti-fog and anti-bacterial films;

2. PE film for heat sealing with ultra-low temperature (starting sealing temperature is as low as 80°C);

3. PE films processed with customer's formula.

Three-layer co-extruded PE films are a type of packaging film that is composed of three layers of polyethylene (PE) materials that are fused together during the extrusion process. These films are commonly used in the pharmaceutical industry to package various types of medication and medical devices.

Multilayer film packaging is crafted using advanced coextrusion technology, resulting in a highly versatile and durable solution. Here are some key features that set our packaging apart:

1. Multiple Layers, Unmatched Strength: Coextruded film is composed of multiple layers meticulously engineered to deliver optimal strength, puncture resistance, and barrier properties. This ensures the protection of your products against moisture, UV light, oxygen, and other potential hazards.

2. Tailored Solutions: We understand that every product has unique requirements. Multilayer films can be customized to meet your specific needs, including thickness, barrier properties, and printing options. Whether you require high clarity for product visibility or enhanced shelf life for perishable goods, our films can be tailored accordingly.

3. Superior Printability: Coextruded films provide excellent printability, allowing you to showcase your brand with vibrant graphics and eye-catching designs. Whether you opt for flexographic, gravure, or digital printing, multi layer packaging ensures exceptional ink adhesion and color consistency, enhancing your product's visual appeal on store shelves.

4. Sustainability Commitment: We believe in protecting both your products and the environment. Multilayer packaging films are designed with sustainability in mind. We offer options made from recyclable materials, as well as films that are compatible with existing recycling streams. By choosing our packaging, you contribute to reducing waste and promoting a greener future.

1. Food and Beverage: Multilayer films for food packaging provides excellent protection for perishable goods, extending their shelf life and ensuring food safety. They are suitable for packaging snacks, fresh produce, dairy products, frozen foods, and beverages.

2. Pharmaceuticals and Healthcare: Coextruded films meet the stringent requirements of the pharmaceutical industry, providing a reliable barrier against moisture, oxygen, and light. They are ideal for packaging medicines, medical devices, and other healthcare products.

3. Industrial and Chemical: Multilayer films offer robust protection for industrial and chemical products, safeguarding them against moisture, chemicals, and external elements. They are suitable for packaging lubricants, adhesives, fertilizers, and more.

4. Personal Care and Cosmetics: Multilayer packaging films provide an attractive and protective packaging solution for personal care and cosmetic products. They offer excellent moisture resistance, preventing product degradation and maintaining the integrity of your formulations.

5. Electronics: Co-extruded films provide electrostatic discharge protection and moisture barrier properties, making them suitable for packaging sensitive electronic components, devices, and accessories.

Choose HySum as your trusted partner for multilayer food packaging, and benefit from our commitment to quality, innovation, and sustainability. Our expertise and dedication ensure that your products receive the packaging they deserve, preserving their freshness, enhancing their appeal, and delivering an outstanding customer experience.

Application: Composite tubes for toothpaste, cosmetics, etc.

Product characteristics:

1、The outer PE film is transparent and flexible, having low crystallizing points and no precipitation; low-temperature heat sealing is available;

2、The inner PE film features high stiffness, low crystallizing point, high frictional stability, and stable additives precipitation.

Application: Condiments, dairy products, and baby food

Product characteristics:

1、Low mobility and precipitation, and no distinctly soluble particles;

2、Film prefabricated bags are inflated and kept in an oven at 50°c for 30 min; they emit no unacceptable odor after being taken out of the oven.

Application: Double-aluminum, pillow-shaped package, strip package and package with three sides sealed with film

Product characteristics:

1、Right-angle tear strength;

2、Used with various composite technologies for simple tearing by hands;

3、One-way or two-way simple tearing is available as needed.

Application: Blister package

Product characteristics:

1、Complete and hygienic strip interface: Seal with/without whitening;

2、Self-seal stripping is available; easy to strip when heat sealed with various materials;

3、The smooth stripping strength curve guarantees the stability and precision of sealing strength.

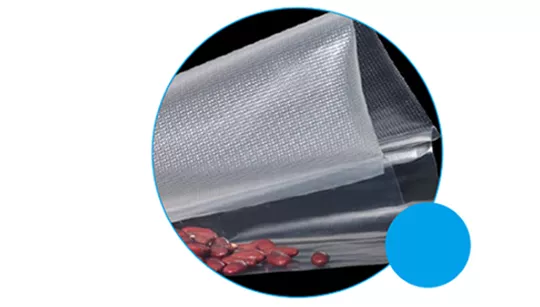

Application: Food preservation

Product characteristics:

1、Continuously preserve food and reduce waste, and appropriately avoid unnecessary costs and environmental burdens associated with excessive packaging;

2、Once the cover film is sealed with hard tray, the co-extruded heat seal film breaks from the M resin layer to expose the pressure-sensitive layer when consumers open the package for the first time; repeated sealing of trays is realized in this way.

Application: Used for the packaging of flour, washing powder, starch, medicine powder and other powders to avoid false sealing and poor sealing caused by powder adsorption on heat sealing face

Product characteristics:

1、Amine-free, low-odor;

2、There is still a good antistatic property after dry compound curing.

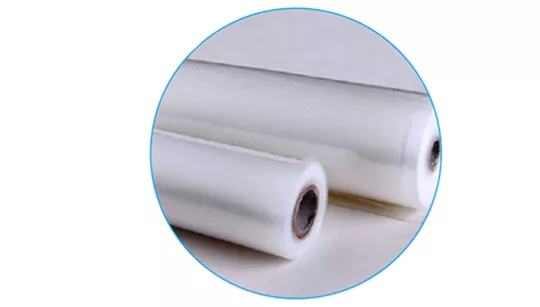

Application: 5~20 kg heavy-duty packaging products

Product characteristics:

1、High yield strength, high tensile strength, and high elongation; the balance between strength and toughness;

2、Low additive precipitation; excellent peel and heat seal strength can be obtained with common polyurethane adhesives;

3、Excellent hot tack strength and low-temperature heat sealability suits automatic filling.